Einführung in den Neigungskoeffizientenprüfer

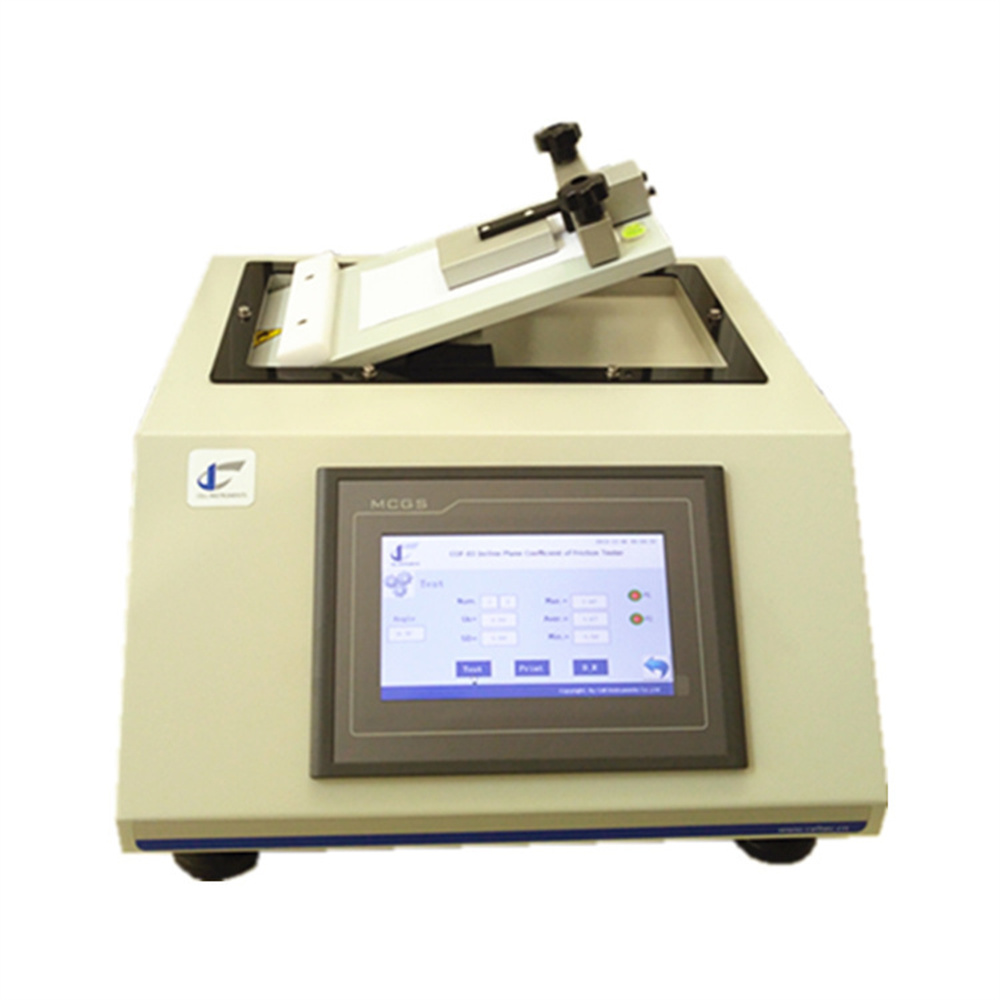

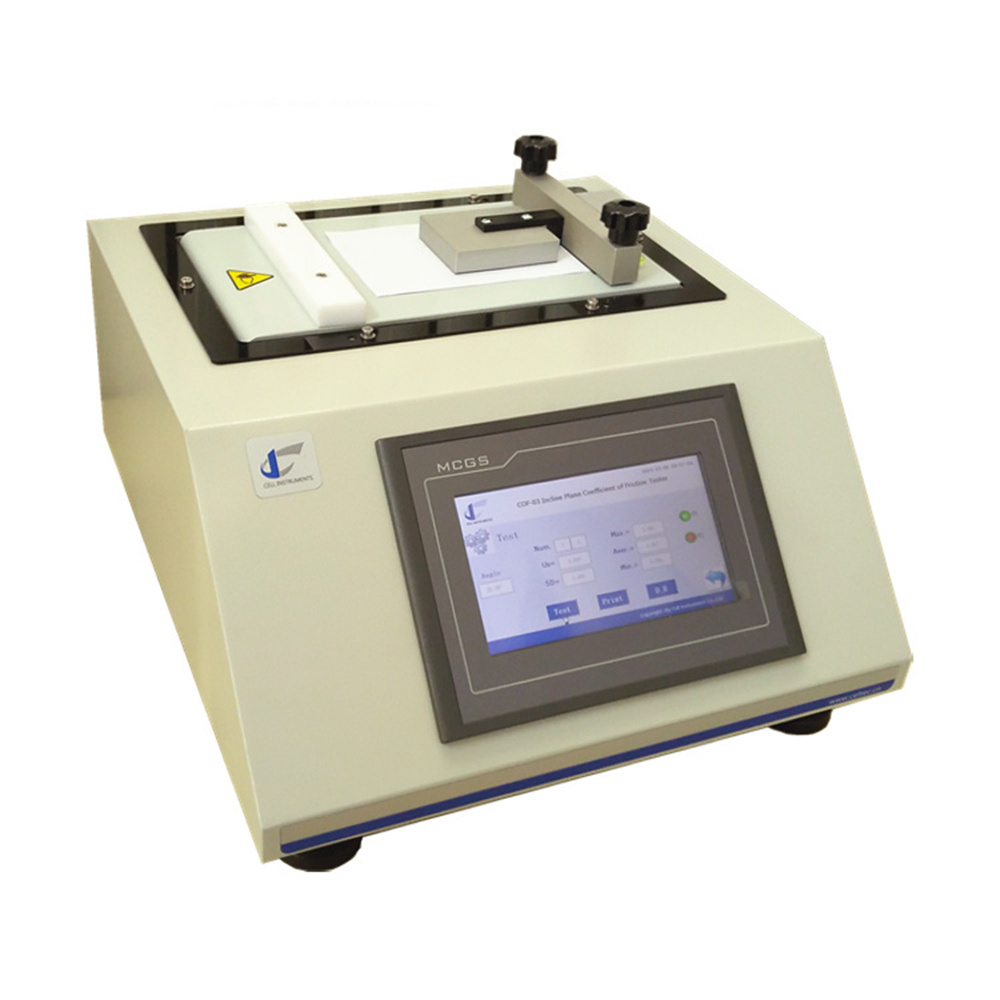

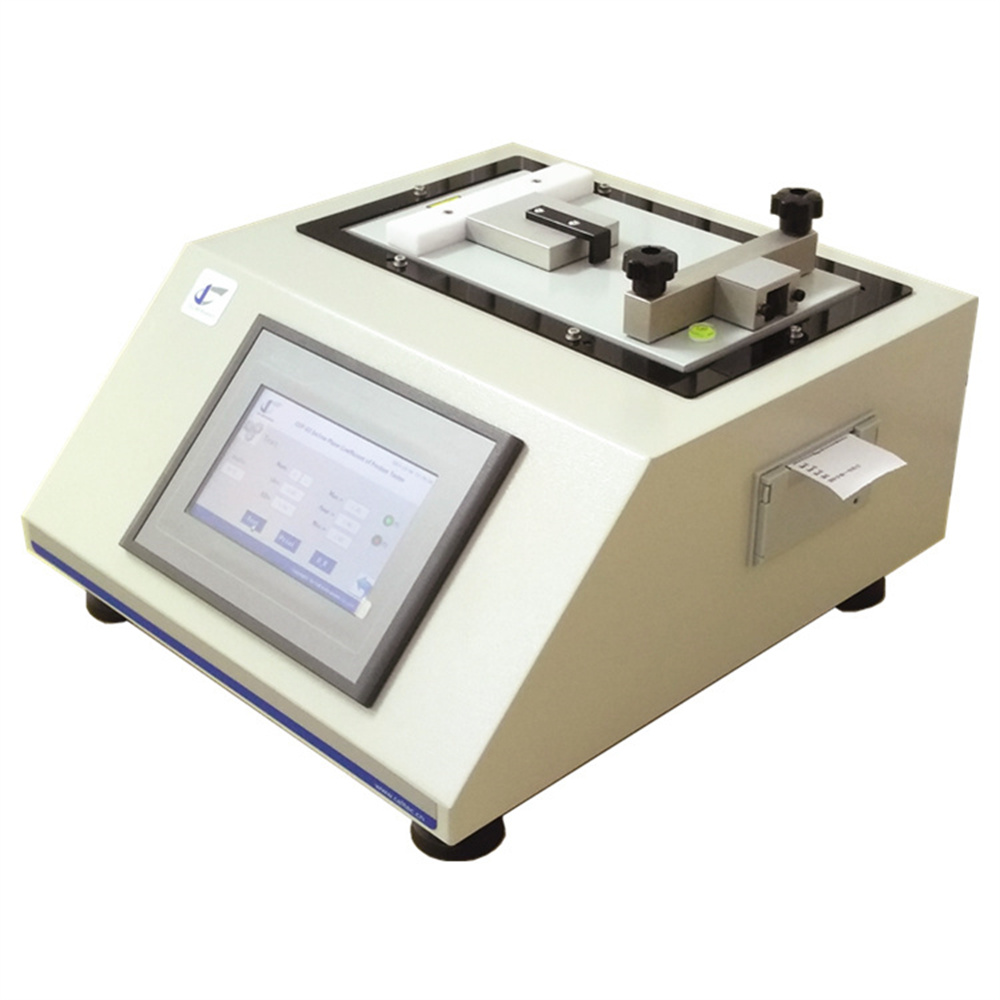

Der Prüfgerät für geneigten Reibungskoeffizienten ist ein fortschrittliches Instrument zur Messung des statischen Reibungskoeffizienten (COF) einer Vielzahl von Materialien. Mithilfe einer variablen schiefen Ebene und eines Gleitblocks bestimmt dieser Tester den Winkel, bei dem eine Testoberfläche beginnt, gegen eine andere zu gleiten, wenn die Neigung allmählich erhöht wird. Das Gerät eignet sich ideal zum Testen verschiedener Materialien, darunter Kunststofffolien, Gummi, Papier, Platten, Gewebe, Beschichtungen, Bremsbeläge, Textilien und mehr.

Dieser vielseitige Tester ist unverzichtbar für Branchen wie die Verpackungs-, Automobil-, Textil-, Pharma- und Lebensmittelverpackungsindustrie, in denen eine genaue Reibungsmessung entscheidend für die Gewährleistung von Qualität, Sicherheit und optimaler Leistung ist. Egal, ob Sie die Reibung von Filmen, Platten oder Industriekomponenten messen müssen, dieses Gerät liefert zuverlässige Ergebnisse und hilft Benutzern, Materialhandhabung, Verpackungsdesign und Produktfunktionalität zu verbessern.

Funktionsprinzip

Der Geneigt Reibungskoeffizientenprüfgerät misst den statischen Reibungskoeffizienten, indem der Winkel bestimmt wird, bei dem ein Material auf einer anderen geneigten Oberfläche zu rutschen beginnt. Wenn die Neigung allmählich mit einer konstanten Geschwindigkeit erhöht wird, beginnt die Oberfläche des getesteten Materials zu rutschen. Der Winkel, bei dem dies geschieht, wird gemessen, und der statische Reibungskoeffizient entspricht numerisch dem Tangens dieses Winkels.

Diese Methode liefert genaue Reibungswerte, die für das Verständnis des Verhaltens von Materialien in realen Anwendungen, wie z. B. bei der Materialhandhabung, Verpackung und Montage, von entscheidender Bedeutung sind. Die Gleitwinkelprüfgerät Die Funktion dieses Instruments gewährleistet, dass für eine große Vielfalt an Materialien genaue COF-Werte erzielt werden.

Übersicht relevanter Prüfnormen

- ASTM D202: Diese Norm bietet Richtlinien für die Messung des statischen Reibungskoeffizienten von Materialien, insbesondere von Folien und Verpackungsmaterialien. Sie stellt sicher, dass der Tester die erforderliche Genauigkeit für eine Reihe von Materialien erreicht, und hilft Herstellern bei der Bewertung, wie leicht Materialien aneinander gleiten, ein Schlüsselfaktor bei Verpackungsdesign und Materialauswahl.

- ASTM D4918: ASTM D4918 wurde speziell für die Prüfung von Papier und Karton entwickelt und beschreibt die Verfahren zur Bestimmung des statischen Reibungskoeffizienten zwischen Papiermaterialien. Diese Norm ist wichtig für Branchen wie die Verpackungs- und Papierproduktion, da sie sicherstellt, dass Materialien die richtigen Reibungseigenschaften für eine reibungslose Handhabung und Verpackungsanwendungen aufweisen.

- TAPPI T815: Dieser in der Papier- und Zellstoffindustrie weithin anerkannte Standard legt die Methode zur Bestimmung des Reibungskoeffizienten von Papier, Karton und verwandten Materialien fest. Er hilft Herstellern sicherzustellen, dass papierbasierte Produkte konsistente Reibungseigenschaften aufweisen, die für den erfolgreichen Betrieb von Verpackungsmaschinen und die Qualität des Endprodukts von entscheidender Bedeutung sind.

Diese Standards stellen sicher, dass die Prüfgerät für geneigten Reibungskoeffizienten erfüllt die notwendigen Kriterien für genaue und zuverlässige Ergebnisse und entspricht den Branchenvorschriften und globalen Best Practices.

Hauptmerkmale des Prüfgeräts für den geneigten Reibungskoeffizienten

- SPS-Steuerung und HMI-Touchscreen-Bedienung: Der Tester verfügt über eine intuitive Mensch-Maschine-Schnittstelle (HMI) und eine speicherprogrammierbare Steuerung (SPS), die die Steuerung und Überwachung des Tests erleichtert. Der Touchscreen ermöglicht eine einfache Navigation und Bedienung und verbessert so die Effizienz und das Benutzererlebnis.

- Echtzeitanzeige der Testergebnisse: Dieses Gerät zeigt Echtzeitdaten auf dem Bildschirm an, einschließlich der maximalen, minimalen, durchschnittlichen und Standardabweichung (SD) der Testergebnisse. So können Sie die Konsistenz und Genauigkeit Ihrer Tests während der Durchführung verfolgen.

- Einhaltung internationaler Standards: Der Prüfgerät für geneigten Reibungskoeffizienten entspricht mehreren internationalen Standards, darunter ASTM D202, ASTM D4918 und TAPPI T815, und gewährleistet so die Genauigkeit und Zuverlässigkeit Ihrer Testergebnisse.

- Messung des Winkel- und statischen Reibungskoeffizienten: Zusätzlich zur Messung des Neigungswinkels, bei dem ein Gleiten auftritt, berechnet dieser Tester auch den statischen Reibungskoeffizienten und bietet so einen umfassenden Überblick über die Materialleistung.

- Mikroschrift zur einfachen Dokumentation von Testergebnissen: Der Tester kann Testergebnisse in gedruckter Form generieren, sodass Benutzer Ergebnisse einfach dokumentieren und weitergeben können. Diese Funktion ist besonders nützlich für die Qualitätskontrolle, Berichterstattung und Konformitätsprüfung.

- Optionale RS232 und professionelle Software: Für Benutzer, die erweiterte Datenanalysen benötigen, bietet der Tester RS232-Konnektivität und optionale professionelle Software, die eine nahtlose Integration mit anderen Systemen ermöglicht und robustere Datenverwaltungs- und Berichterstellungsfunktionen bietet.

Technische Spezifikationen

| Winkelbereich | 0° ~ 60° |

| Genauigkeit | 0,01° |

| Schlaganfall | 0,1°/s ~ 10,0°/s |

| Schlitten | 200 g, 235 g oder 1300 g (wählen Sie eine oder mehrere aus) |

Anwendungen des geneigten Reibungskoeffizientenprüfers

Der Prüfgerät für geneigten Reibungskoeffizienten wird in vielen Branchen eingesetzt, um Materialien auf Reibungseigenschaften zu testen. Hier sind einige wichtige Anwendungen:

- Verpackung: Bewerten Sie die Reibungseigenschaften von Folien, Papier, Karton und anderen Verpackungsmaterialien, um einen reibungslosen Betrieb in Verpackungslinien zu gewährleisten.

- Automobilindustrie: Bewerten Sie Bremsbeläge und andere Komponenten hinsichtlich Leistung, Haltbarkeit und Sicherheit.

- Textilien: Testen Sie Stoffe, Gewebe und Beschichtungen auf ihre Reibungseigenschaften, die für die Handhabung und Verarbeitung von Stoffen wichtig sind.

- Medizinische Geräte: Stellen Sie sicher, dass medizinische Verpackungsmaterialien die erforderlichen COF-Anforderungen erfüllen, um Probleme während der Verpackung und Verteilung zu vermeiden.

- Pharmazeutika: Messen Sie die Reibungseigenschaften von Verpackungsmaterialien für Arzneimittel, um eine ordnungsgemäße Handhabung und Lagerung sicherzustellen.