In the realm of packaging, ensuring the integrity and durability of materials is paramount to maintaining product safety. One crucial method to achieve this is through burst test packaging, a procedure designed to simulate the pressures packages might encounter during shipping and handling. This article will delve into the importance of burst test packaging, specifically focusing on the standards ASTM F1140 and ASTM F2054, which govern these testing methods.

Understanding Burst Test Packaging

Burst test packaging is a vital quality assurance process used across various industries, including pharmaceuticals, food, medical devices, and electronics. By applying controlled pressure to a package until it bursts, manufacturers can identify weak points and ensure that their packaging can withstand real-world conditions without failing. This test is essential for preventing product damage, ensuring consumer safety, and maintaining brand reputation.

ASTM F1140 and ASTM F2054: Key Standards for Burst Testing

ASTM F1140

ASTM F1140 outlines the procedures for testing the resistance of packaging to internal pressurization. This standard is applicable to various package forms, including sealed trays and cups. The test involves securing the package in a fixture, pressurizing it with air or other gases, and monitoring it until it bursts or leaks. The pressure at which the package fails is recorded to assess its strength and durability.

ASTM F2054

ASTM F2054 provides guidelines for burst testing flexible packages. Similar to ASTM F1140, this method involves inflating a package with air until it bursts, recording the pressure at which it fails. Compliance with ASTM F2054 ensures consistency and reliability in burst testing, providing a benchmark for quality assurance and helping manufacturers meet industry standards.

The Importance of Burst Test Packaging in Ensuring Product Safety

Pharmaceutical Industry

In the pharmaceutical industry, maintaining the integrity of packaging is critical for patient safety. Burst test packaging helps ensure that containers can withstand pressure without bursting, thereby protecting sensitive medications from contamination and damage.

Food Industry

For the food industry, strong packaging is essential to keep products fresh and uncontaminated. Burst test packaging verifies that packaging materials can endure the rigors of transportation and handling, preserving product quality until it reaches the consumer.

Medical Devices and Other Industries

Medical devices, electronics, and other sensitive products also rely on robust packaging to prevent damage during transit. Burst test packaging plays a crucial role in these industries by confirming that packaging can protect products effectively.

Key Features of Burst Testing Machines

User-Friendly Interface

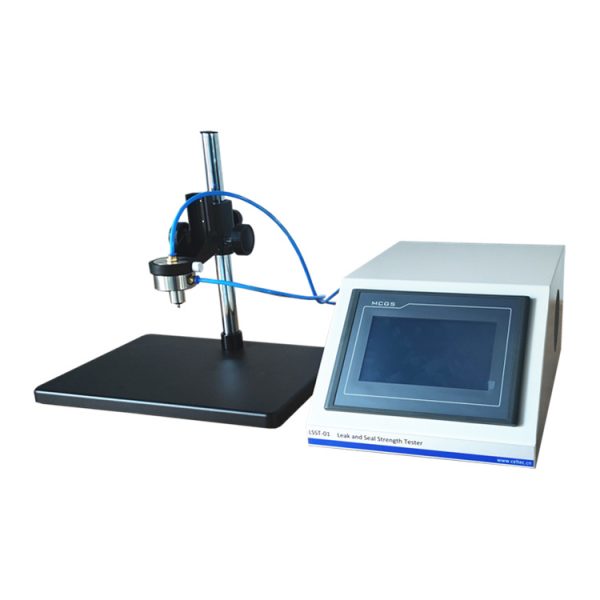

Modern burst testing machines, like the ones offered by Cell Instruments, feature a user-friendly interface for ease of use. These machines are equipped with a touch screen HMI (Human-Machine Interface) and PLC-controlled units for industrial-level stability.

Automatic Test Result Statistics and Storage

These machines automatically calculate and store test results, facilitating easy data management and analysis. This feature saves time and reduces human error, making the testing process more efficient.

Compatibility with Various Fixtures

Burst testing machines are compatible with a variety of fixtures, allowing them to test different package forms, including open packages, closed packages, doy packs, tubes, sealed trays, and cups. This versatility ensures comprehensive testing capabilities.

Multiple Test Modes

With test modes such as burst, creep, and creep to failure, these machines provide thorough testing of package strength and durability under different conditions.

How to Perform Burst Testing According to ASTM Standards

Procedure for ASTM F2054

- Place the package in the testing machine.

- Inflate the package with air at a controlled rate.

- Record the pressure at which the package bursts.

- Analyze the data to assess the package’s strength and durability.

Procedure for ASTM F1140

- Secure the package in the testing fixture.

- Pressurize the package using air or other gases.

- Monitor the package until it bursts or leaks.

- Record the pressure at which the failure occurs.

Benefits of Using Cell Instruments’ Package Burst Testing Machine

Enhanced Product Safety

Using Cell Instruments’ package burst testing machine enhances product safety by ensuring that packaging can withstand real-world conditions without failing. This testing helps prevent product damage and contamination, protecting consumers.

Cost Efficiency

By identifying weak points in packaging, the machine helps reduce product returns and damage-related costs. It also minimizes material waste by optimizing package design, leading to cost savings.

Customization and Support

Cell Instruments offers customizable solutions to meet unique testing requirements. Their team provides comprehensive support, from initial setup to ongoing maintenance, ensuring that your testing needs are met efficiently.

After-Sales Support and Maintenance Services

A dedicated support team offers after-sales support and maintenance services, ensuring that your package burst testing machine operates smoothly and efficiently. This support helps maximize the machine’s lifespan and reliability.

Frequently Asked Questions

1. What is burst test packaging?

Burst test packaging is a quality assurance process that involves applying controlled pressure to a package until it bursts, to identify weak points and ensure durability.

2. Why is compliance with ASTM F1140 and ASTM F2054 important?

Compliance with these standards ensures consistency and reliability in burst testing, providing a benchmark for quality assurance and helping manufacturers meet industry standards.

3. What industries benefit from burst test packaging?

Industries such as pharmaceuticals, food, medical devices, electronics, and others benefit from burst test packaging by ensuring their products are protected during transit.

4. What are the key features of Cell Instruments’ package burst testing machine?

Key features include a user-friendly interface, automatic test result statistics and storage, compatibility with various fixtures, multiple test modes, and customizable sensitivity and threshold settings.

5. How does burst test packaging enhance product safety?

By ensuring that packaging can withstand real-world conditions without failing, burst test packaging helps prevent product damage and contamination, protecting consumers.