مقدمة عن جهاز اختبار سمك لوح الورق

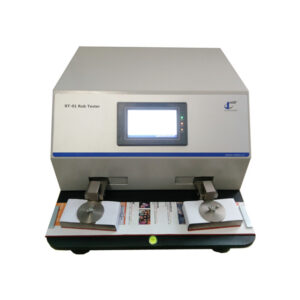

ال جهاز اختبار سمك لوح الورق PBT-01 جهاز PBT-01 هو جهاز متقدم عالي الدقة مصمم خصيصًا لقياس سمك صفائح مفردة من الورق المقوى المموج. يلعب هذا الجهاز دورًا حيويًا في مراقبة جودة مواد التغليف، حيث تعد قياسات السمك الدقيقة ضرورية لتحديد متانة وقوة الورق المقوى المستخدم في تصنيع صناديق التعبئة والتغليف وحلول التغليف الأخرى. مناسب لجميع أنواع الورق المقوى المموج، يضمن جهاز PBT-01 أن مواد التغليف تلبي معايير الجودة الصارمة للحماية والموثوقية.

أهمية القياس الدقيق للسمك في التغليف

يعد قياس السُمك الدقيق أمرًا بالغ الأهمية في صناعة التعبئة والتغليف، حيث يؤثر الاتساق في سُمك اللوحة على الصفات الوقائية والسلامة البنيوية للمنتج النهائي. جهاز اختبار سمك لوح الورق PBT-01 يساعد المصنعين ومحترفي مراقبة الجودة على التحقق من أن كل ورقة تلبي متطلبات السُمك الدقيقة، مما يحسن أداء المواد ويساعد في الحفاظ على جودة المنتج أثناء النقل. يمنع قياس السُمك الموثوق به هدر المواد، ويعزز استقرار التغليف، ويحافظ على الامتثال التنظيمي لجودة التغليف.

مبدأ الاختبار ومنهجية اختبار سمك لوح الورق

- مبدأ قياس السُمك يقيس جهاز PBT-01 سمك اللوح المموج عن طريق وضع عينة اللوح بين وجهين دائريين متوازيين للضغط تحت حمل ثابت محدد. يطبق هذا الاختبار عالي الدقة الضغط اللازم لالتقاط سمك اللوح بدقة لا مثيل لها.

- طريقة اختبار سمك الإزاحة باستخدام طريقة اختبار سمك الإزاحة، يستخدم جهاز PBT-01 وجهًا ثابتًا (السندان) ووجهًا متحركًا يطبق ضغطًا موحدًا أثناء قياس السمك. يمارس الوجه المتحرك ضغطًا ثابتًا يبلغ 20 كيلو باسكال ± 0.5 كيلو باسكال، مما يضمن دقة النتائج وقابليتها للتكرار. الجهاز قادر على قياس سمك يتراوح من 0 إلى 20 مم، بدقة 0.001 مم، مما يجعله خيارًا موثوقًا به لكل من احتياجات الاختبار القياسية والمتخصصة.

هيكل الجهاز والمواصفات الفنية

- مناطق الضغط ومناطق التلامس تم تصميم وجهي الضغط الدائريين لجهاز PBT-01 لتحقيق الدقة المثلى. يكون السندان ثابتًا، بينما يتحرك الوجه الثاني بشكل عمودي لتطبيق الضغط بالتساوي بمعدل 2 مم/ثانية إلى 3 مم/ثانية. يبلغ قطر وجهي الضغط الدائريين 35.7 مم ± 0.3 مم، مع مساحة اتصال تبلغ 1000 مم² ± 20 مم². يضمن هذا التكوين توزيع ضغط الاختبار بشكل موحد، مما يعطي قراءات دقيقة للسمك.

- المميزات التقنية يتضمن جهاز اختبار سمك لوح الورق PBT-01 ميزات تقنية أساسية:

مدى الاختبار 0~20 ملم دقة 0.001 مم منطقة الاتصال 1000±20 مم² ضغط الاتصال 20±2 كيلو باسكال قياس التوازي السطحي ≤0.035 مم خطأ العرض ±0.05٪

الامتثال لمعايير الصناعة

تم تصميم جهاز اختبار سمك لوح الورق PBT-01 بما يتماشى مع معايير الصناعة لاختبار ألواح الألياف المموجة ومواد التغليف، مما يضمن تلبية متطلبات الدقة الفنية لهذه الإرشادات. يعد الالتزام بهذه المعايير أمرًا ضروريًا للحصول على قياسات موثوقة ومتسقة في تطبيقات التغليف الاحترافية، مما يعزز دور جهاز الاختبار في توفير مراقبة الجودة والامتثال عبر الصناعات.

مميزات جهاز اختبار سمك لوح الورق PBT-01

يقدم PBT-01 مزايا فريدة تجعله متميزًا في مجال اختبار المواد:

- دقة عالية: بفضل الدقة التي تبلغ 0.001 مم، يضمن جهاز PBT-01 إجراء قياسات عالية الدقة لمراقبة الجودة بشكل موثوق.

- تطبيقات متعددة: مناسب لجميع أنواع ألواح الألياف المموجة، مما يجعله خيارًا متعدد الاستخدامات لأنواع التغليف المختلفة.

- تصميم سهل الاستخدام: تعمل الميزات مثل وظيفة إعادة الضبط ZERO وأدوات التحكم البسيطة في الطاقة على تعزيز سهولة الاستخدام.

- تحسين مراقبة الجودة: ضمان قياس ثابت للسمك لتحسين متانة التغليف وتوفير المواد.

التطبيقات عبر الصناعات

يُعد جهاز اختبار سمك لوح الورق PBT-01 قابلاً للتطبيق على نطاق واسع في مختلف الصناعات، بما في ذلك التعبئة والتغليف والأغذية والأدوية ووكالات فحص الجودة. بفضل قياساته الدقيقة والمتسقة، يتيح مقياس سمك PBT-01 للشركات الحفاظ على رقابة صارمة على جودة مواد التعبئة والتغليف، مما يدعم تطوير حلول التعبئة والتغليف المتينة والموثوقة في مختلف القطاعات.

الأسئلة الشائعة

- ما هي ألواح الألياف المموجة؟

- تتكون ألواح الألياف المموجة من ورقة أو أكثر من الورق المموج الملتصقة بورقة مسطحة من الورق المقوى أو بين عدة أوراق. وهي مادة شائعة الاستخدام في التغليف بسبب قوتها وخصائصها في امتصاص الصدمات.

- ماذا يقصد بـ “سمك الطبقة الواحدة من الورق المقوى المموج”؟

- يشير سمك الطبقة الواحدة إلى المسافة بين أحد أسطح لوح الألياف المموج والسطح المقابل، والتي يتم قياسها تحت حمل ثابت محدد مطبق.

- ما مدى دقة جهاز PBT-01 في قياس السمك؟

- يوفر PBT-01 دقة عالية بدقة 0.001 مم ومعدل دقة ±0.05%، مما يجعله خيارًا موثوقًا به للقياسات المتسقة والقابلة للتكرار.

- لماذا يعد ضغط التلامس مهمًا في اختبار السُمك؟

- يضمن تطبيق ضغط اتصال ثابت أثناء الاختبار أن القياس يعكس بدقة سمك اللوحة دون فروق ضغط، وبالتالي توفير نتائج قابلة للتكرار وموثوقة.

- ما هي الصناعات التي تستفيد من استخدام جهاز اختبار السمك PBT-01؟

- يعد PBT-01 ضروريًا للتغليف والأغذية والأدوية وغيرها من الصناعات حيث تكون جودة المواد وموثوقية التغليف أمرًا بالغ الأهمية لحماية المنتج وسلامته.