Introduction to Hot Tack Test

ال hot tack test is a critical evaluation method that measures the strength of heat seals immediately after sealing and before the seal cools. This test is essential in industries where quick and reliable sealing is required, especially in vertical form-fill-seal (VFFS) processes. A strong hot tack ensures the seal remains intact when the package is filled with products, preventing spills and maintaining product integrity.

Hot tack testing is widely used in industries such as food packaging, pharmaceuticals, adhesives, and electronics, where packaging performance directly impacts product safety and quality.

Overview of Heat Seal Testing

Heat seal testing assesses the overall strength, durability, and flexibility of thermoplastic materials after sealing. It ensures that seals can withstand handling, storage, and transport conditions. Key factors influencing heat seal performance include:

- Sealing temperature

- ضغط

- Dwell time

- Cooling time

Accurate control of these parameters is crucial to achieving consistent and reliable seals, making heat seal testing a cornerstone of quality assurance in flexible packaging.

ASTM F1921 و معايير ASTM F2029 المعايير

- ASTM F1921:

This standard outlines test methods for determining hot seal strength (hot tack) of thermoplastic materials. It provides guidelines on sealing conditions, test procedures, and measuring the force required to separate seals. - معايير ASTM F2029:

This standard describes practices for making heat seals and evaluating their strength. It ensures that heat-sealable materials meet performance criteria by specifying parameters for sealing and testing.

Both standards are crucial for maintaining quality control and ensuring compliance with industry regulations.

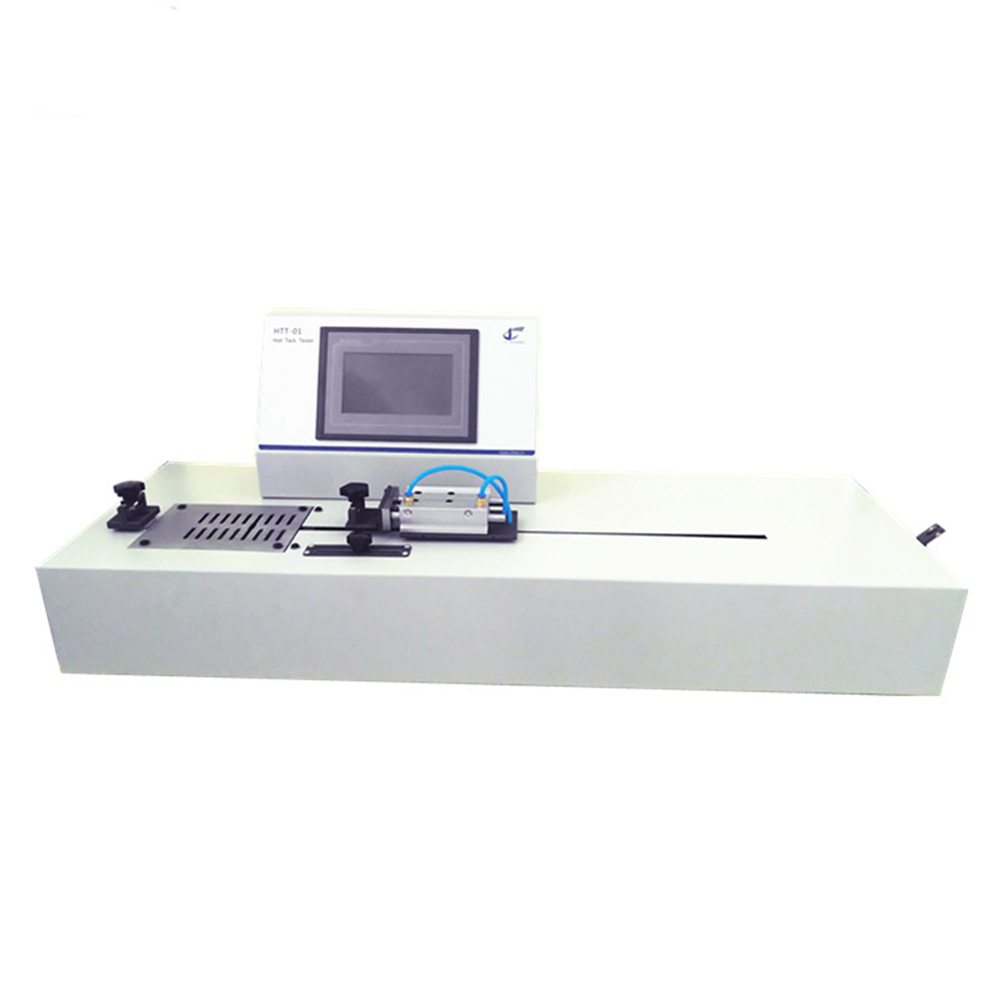

HTT-01 Hot Tack and Tensile Tester

ال HTT-01 Hot Tack and Tensile Tester is a versatile instrument designed to evaluate both hot tack and overall قوة الختم of thermoplastic materials. It provides reliable data for quality assurance in packaging applications and helps manufacturers optimize their sealing processes.

Key Applications:

- Hot tack testing for VFFS packaging.

- Heat seal strength evaluation for flexible webs.

- Tensile and peel force testing of thermoplastic materials.

Testing Principle and Process

The hot tack test involves sealing a sample strip between two heated jaws under controlled conditions:

- Sealing Parameters: Temperature, dwell time, pressure, and cooling time are set according to the material specifications.

- Separation Test: After sealing, the sample is separated at a specified speed, and the force required to break the seal is measured.

The resulting force indicates the hot tack strength, which is critical for ensuring packaging performance in real-world applications.

Key Technical Features of HTT-01

- Advanced Control and Interface:

The HTT-01 features a PLC-controlled system with an شاشة لمس HMI interface, ensuring industrial-level stability and user-friendly operation. - قدرات الاختبار المتنوعة:

It supports hot tack, tensile, and peel testing, making it a multi-functional solution for various applications. - Temperature Precision:

The tester uses a Delta P.I.D. temperature controller و PT100 sensor for accurate temperature control, ensuring repeatable results. - Adjustable Parameters:

Users can customize sealing temperature, pressure, and dwell time, with testing speeds ranging from 1 to 2000 mm/min. - Safety and Data Management:

The HTT-01 includes safety features such as auto zeroing, overload protection، و over-travel protection. Data can be managed via an RS 232 port and optional professional software.

Main Technical Specifications

| درجة حرارة الختم. | Ambient~250℃ |

| Temp Accuracy | ±0.2 درجة مئوية |

| وقت الإقامة | 0.1~9999s(Heat Seal ) |

| وقت الإقامة | 0.1~9999s(Hot Tack ) |

| ضغط الختم | 0.15MPa~0.7MPa |

| Sealing Jaws | 50mmx10mm Teflon Coated |

| Jaws Heating | Double Heating |

| خلية الحمل | 200N(Optional:30N50N100N, etc) |

| دقة | 0.5 F.S. |

| دقة | 0.01 نيوتن |

| قوة | 220V, 50 HZ |

Significance of Hot Tack and Heat Seal Testing

- Ensuring Quality and Safety:

Hot tack and heat seal tests play a vital role in maintaining the quality and safety of packaged goods. By assessing seal strength at different stages, manufacturers can prevent product spills and failures. - Industry Compliance:

Adhering to ASTM F1921 و معايير ASTM F2029 ensures that products meet industry standards and customer expectations. - Optimizing Processes:

The data gathered from hot tack and heat seal tests help optimize packaging processes, improving efficiency and reducing waste.

ال HTT-01 Hot Tack and Tensile Tester is an essential tool for ensuring the integrity and reliability of heat seals in flexible packaging. By adhering to ASTM F1921 و معايير ASTM F2029 standards, this tester helps manufacturers achieve consistent quality and meet industry requirements. Its advanced features, precision controls, and versatility make it a valuable asset in packaging quality assurance.

الأسئلة الشائعة

- What is a hot tack test, and why is it important?

The hot tack test measures the strength of a heat seal immediately after sealing, critical for maintaining package integrity in high-speed processes. - How does heat seal testing differ from hot tack testing?

Heat seal testing evaluates the overall strength of the seal after cooling, while hot tack testing assesses the seal strength before cooling. - What industries use hot tack and heat seal testing?

Industries such as food packaging, pharmaceuticals, adhesives, and electronics rely on these tests to ensure product safety and quality. - What are ASTM F1921 and ASTM F2029?

ASTM F1921 provides methods for evaluating hot tack strength, while ASTM F2029 outlines practices for making and assessing heat seals. - What are the key features of the HTT-01 Hot Tack Tester?

The HTT-01 offers advanced control, versatile testing capabilities, precise temperature control, and robust safety features, making it ideal for comprehensive heat seal testing.